|

|

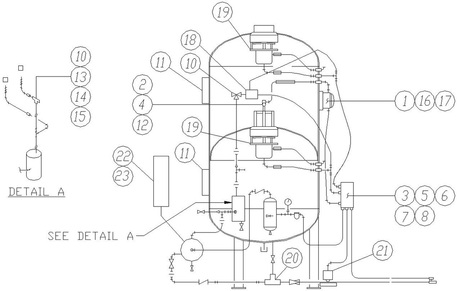

This is for Automatic Blast Vessel Component (Model MSA) Part numbers 21006203 level probe socket, 21005612 level control, 21005622 level control din mount, 21005700 level probe non ferrous, 22010320 Time delay relay, 29065020 selector switch 2-position, 30000840 air cylinder 2.5" x 9", 30000850 rotary actuator cylinder, 31003950 3-way exhaust ball valve, 44001210 11 x 15 manway gasket, 44001216 12 16 manway gasket, 69110010 level probe steel grit, 74000010 3-way ball seal kit, 74000011 3-way ball valve ball, 74000012 3-way ball valve stem, 74000014 level probe control non ferrous, 74000016 level probe head and rod only non ferrous, 30000850 3-way ball valve actuating cylinder, 30000851 3-way ball valve cylinder mount, 69020030 abrasive charge valve, 69020021 metering valve 1 1/2", 69020015 Pinch valve stomper valve, 74400815 silencer 2" muffler, 74400825 silencer muffler 2" filter element, 31001800 rupture disc 1 1/2".

|

We recommend that our customers keep a spare charge valve on hand. When the charge valve needs to be repaired (new cylinder or rubber ring), we suggest they remove the whole unit from the vessel and replace with the on-hand spare. Then, any necessary repairs can be done on the bench with less time pressure and better working conditions. Repair the charge valve and put it back on the shelf for next time it is needed.

An abrasive charge valve allows the upper chamber of a dual chamber vessel to fill while the lower chamber remains pressurized. When the grit supply in the lower chamber needs to be replenished, the internal charge valve opens allowing the abrasive to fall into the lower chamber from the upper chamber. Because the operators can continue working during this process, efficiency and production is greatly increased.

An abrasive charge valve allows the upper chamber of a dual chamber vessel to fill while the lower chamber remains pressurized. When the grit supply in the lower chamber needs to be replenished, the internal charge valve opens allowing the abrasive to fall into the lower chamber from the upper chamber. Because the operators can continue working during this process, efficiency and production is greatly increased.