|

|

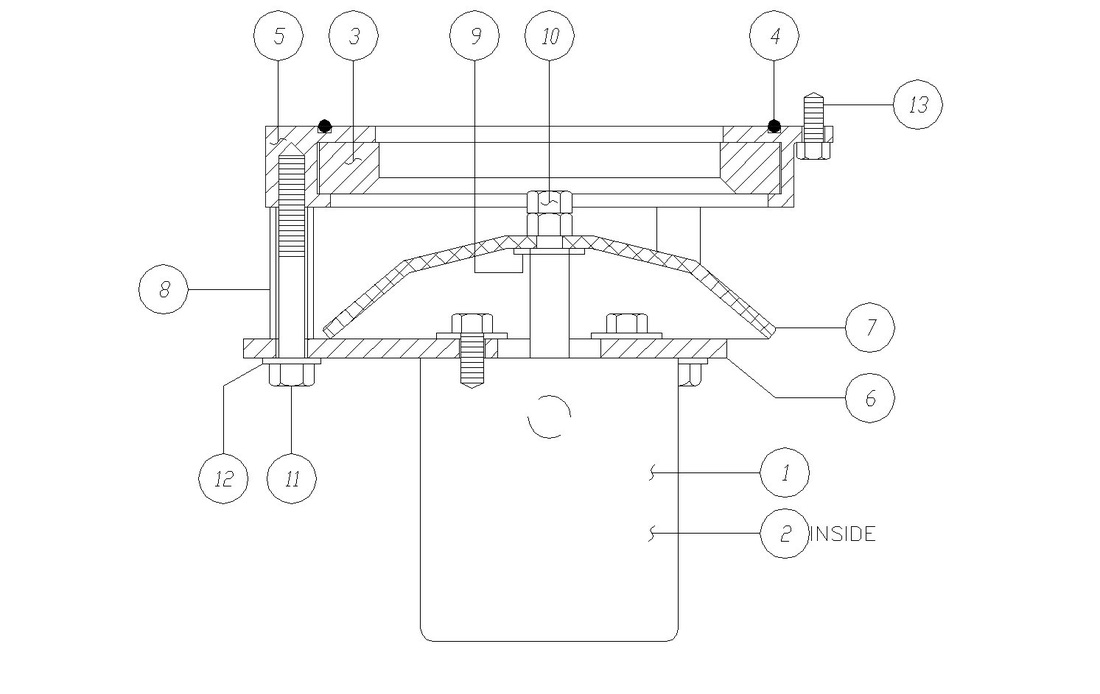

This is for Abrasive Charge Valve Part numbers 6902-0030 Charge Valve complete, 30000830 Air cylinder, 30000833 Cylinder repair kit, 69020030D Charge Valve complete Double Acting Cylinder, 30000835 Cylinder Double Acting, 43001250 Hex bolt M12, 44001760 Rubber ring, 44001778 o-ring, 62030030 Retainer ring, 6304-0035 Retainer ring with rubber, 62030080 Spider, 62030085 Plug, 62030090 Spacer, 62030095 Washer, 74300101 Jam Nujts, 74300102 Hex Bolt, 74300103 Lock washer, 43000457 Allen head screw, 62030086 Urethane pop-up Valve plug.

|

An essential part of an automatic blast vessel, the abrasive charge valve allows the upper chamber to fill while the lower chamber remains pressurized. When the grit supply in the lower chamber needs to be replenished, the internal charge valve opens, allowing the abrasive to fall into the lower chamber from the upper chamber. Because the operators can continue working during this process, efficiency and production is greatly increased.

We recommend that our customers keep a spare charge valve on hand to reduce downtime. When the charge valve needs to be repaired (typically a new cylinder, diaphragm repair kit or rubber ring), we suggest they remove the entire unit from the vessel and replace with the on-hand spare. Then, any necessary repairs can be done on the bench using less time and with better working conditions. Repair the charge valve and put it back on the shelf for next time it is required.

We recommend that our customers keep a spare charge valve on hand to reduce downtime. When the charge valve needs to be repaired (typically a new cylinder, diaphragm repair kit or rubber ring), we suggest they remove the entire unit from the vessel and replace with the on-hand spare. Then, any necessary repairs can be done on the bench using less time and with better working conditions. Repair the charge valve and put it back on the shelf for next time it is required.